CERTIFICATIONS

CERTIFICATIONS

Services & Capacity

Our production capacity is highly adaptable and varies based on the complexity and volume of each design.

Product Development

- pattern making CAD

- prototypes sewing

- salesmen samples making

- placements and plotting

Cut & Make

- cutting

- sewing

- packing

- packaging

Cut & Make & Trims

- trims sourcing

- cutting

- sewing

- packing

- packaging

Optional Services

* outsourced specialised companies

- embroidery / laser cut

- pleating (manual/machine)

- washing / special treatments

- transport of finished goods

CAPACITY

Our production capacity is highly adaptable and varies based on the complexity and volume of each design.

For larger volume orders, our capacity significantly increases to accommodate the demand efficiently.

Conversely, for smaller, more intricate orders, our capacity adjusts to maintain our high standards of quality and precision.

MOQ

We are flexible with our Minimum Order Quantities (MOQ), typically set at 1,000 pieces per style.

We can adjust this for larger production runs and higher total volumes.

Our pricing methodology uses tailored coefficients to accommodate each client's specific needs.

LEAD TIME

While delays may arise throughout the supply chain, we are committed to adapting our production planning with flexibility and efficiency to try meeting the clients target delivery.

PRODUCTION CHAINS

We operate with 7 distinct production assembly chains, allowing us to manage and streamline different stages of manufacturing for optimal efficiency and quality.

- 2 internal assembly chains

(GOTS, BSCI, SMETA, ISO)

- 5 outsourced assembly chains

(BSCI, SMETA)

QUALITY CONTROL

- 2 QC - internal chains

- 6 QC - outsourced chains

- 2 QC - second control of bulk production (AQL)

EMPLOYEES

40% back office:

technical office (pattern makers, sampling operators, plotting), QC, warehouse, commercial, financial

60% production:

cutting room, assembly chains, packaging

WHAT SETS US APART

QUALITY IS OUR

PRIORITY

In both client servicing and product sewing, throughout the process we make sure that every garment we bring to life reflects our commitment to excellence.

COMMUNICATION

IS KEY

We prioritise quick and efficient communication, and expect the same from our partners, ensuring that every interaction and update throughout the production process is handled promptly and accurately to meet our clients' needs.

PRODUCTION PLANNING

FLEXIBILITY

We do our utmost to maintain adaptable and responsive production schedules, accommodating changes and meeting our clients' diverse needs efficiently and effectively.

EXPERTISE

Discover Our Range: Showcasing diverse product categories

that highlight our expertise and commitment to quality and innovation.

Expertise in fabrics from natural silk to wool blend

DRESSES

Work with tafetta, crepe, silk and many other more

BLOUSES

From cotton poplin to natural silk or blends

SHIRTS

Mini, midi, maxi, plain or pleated, from silk to tweed

SKIRTS

From classic tailored trousers, to daring couture designs

TROUSERS

From casual to tailored blazers

BLAZERS / OVERSHIRTS

From lighter fabrics to raincoats

JACKETS

Non-structured coats, short, midi or long

COATS

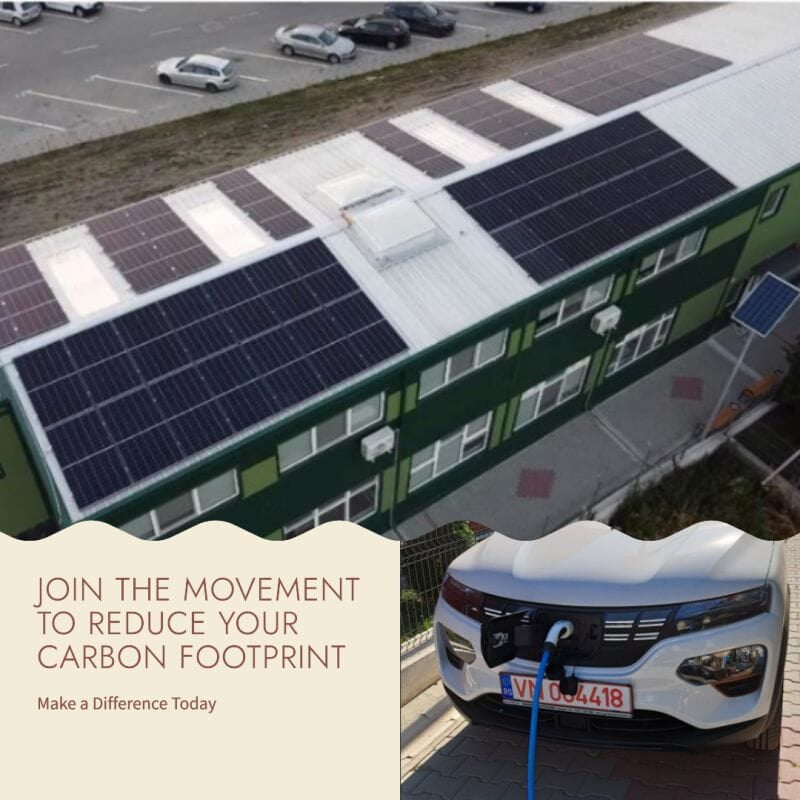

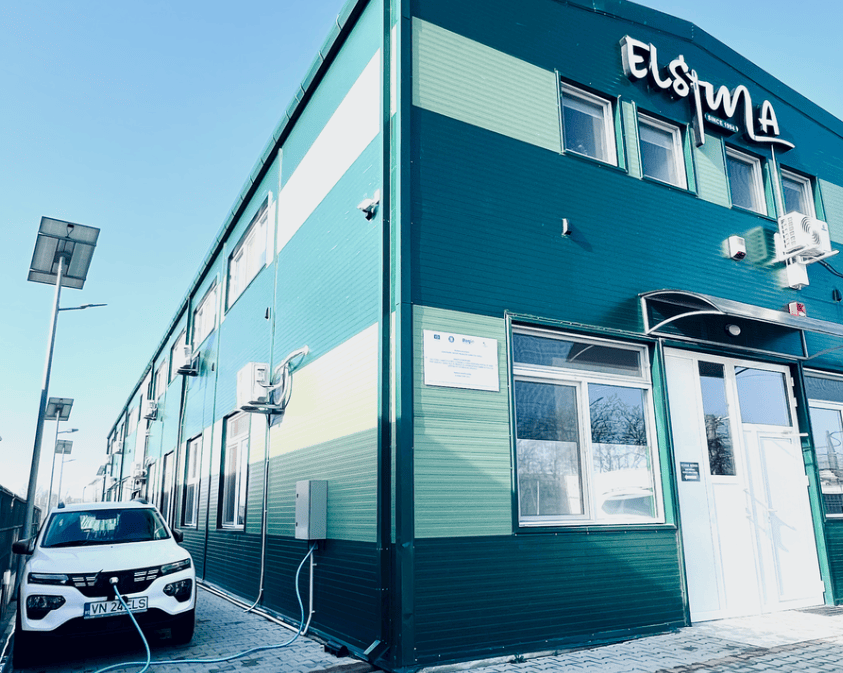

OUR FACTORY

Welcome to Our New Factory: A modern facility powered by green energy,

housed in our own building, dedicated to sustainable and innovative manufacturing.

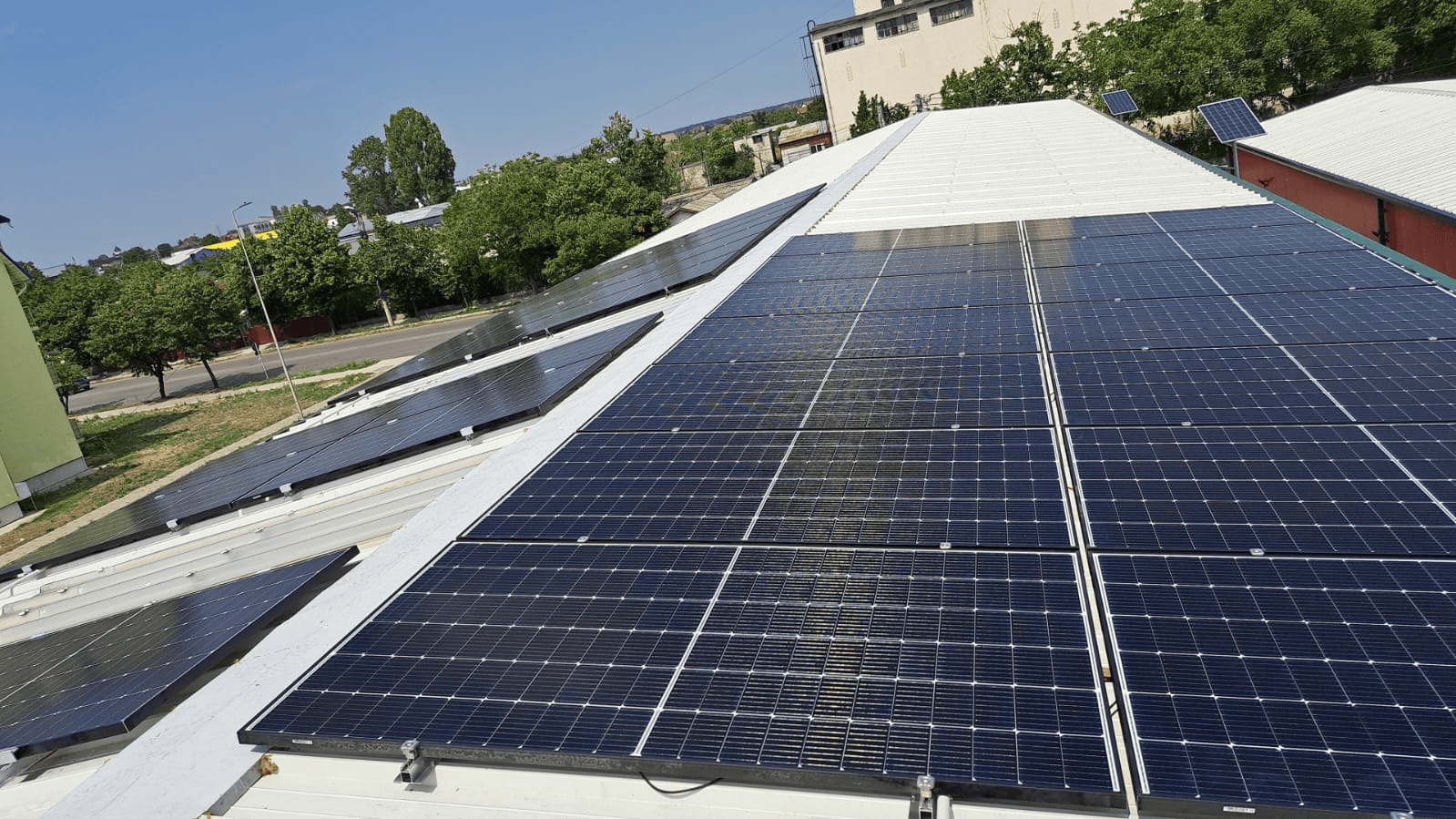

June-2023 is one of the most important milestones.

We have implemented a photovoltaic system at our factory

and acquired the first electric car.

This is a great way to reduce our carbon footprint.

We are proud to be part of the green revolution and contribute to a more sustainable future.

CERTIFICATIONS

CERTIFICATIONS

EQUIPMENT

Comprehensive Production Equipment: Our facility is equipped with advanced machinery for every stage of production,

from cutting and sewing to finishing and quality control, ensuring precision and excellence in every product.

RAW MATERIALS WAREHOUSE

- each client's inventory is meticulously stored separately, organized on shelves and pallets

- this rigorous separation ensures precision in inventory management and facilitates efficient access to materials tailored to each client's specific needs

- equipped with Electric Material Handling Machine

TECHNICAL OFFICE

- fluency in English, French, Italian

- 4 pattern makers - CAD GEMINI Lectra system

- 8 sample makers

- 1 ironing operator

- 1 placements & plotting operator - GEMINI system

- 1 office assistant

- 1 team leader

CUTTING ROOM

- 3 manual cutting tables

- 3 fabric layering tables

- 1 fusing machine 90cm width

ASSEMBLY CHAINS

Suction & Blowing Ironing Tables

1-needle Lockstitch Machines

2-needle Lockstitch Machines

1-needle Overlock Machines with 3 threads

2-needle Overlock Machines with 4, 5 threads

Buttonhole Machines (Straight & Eyelet buttonhole)

Coverstich Machines

Pattern Stitching Machine

Pinpoint Sewing Machine

Double Chainstitch Machine

Triple Transport Column Machine

Blindstitch Machines (normal & hidden)

Automatic Pocket Welt Machines

Sewing & Edge Cutting Machines

Snap Machines

Bartacking Machines

Zig-Zag Stitching Machine

Button Sewing Machine

Optimized Machine for Applying Sleeves

AMF Stitching Machine

Embroidery Machine (15 needles, 2 panels)

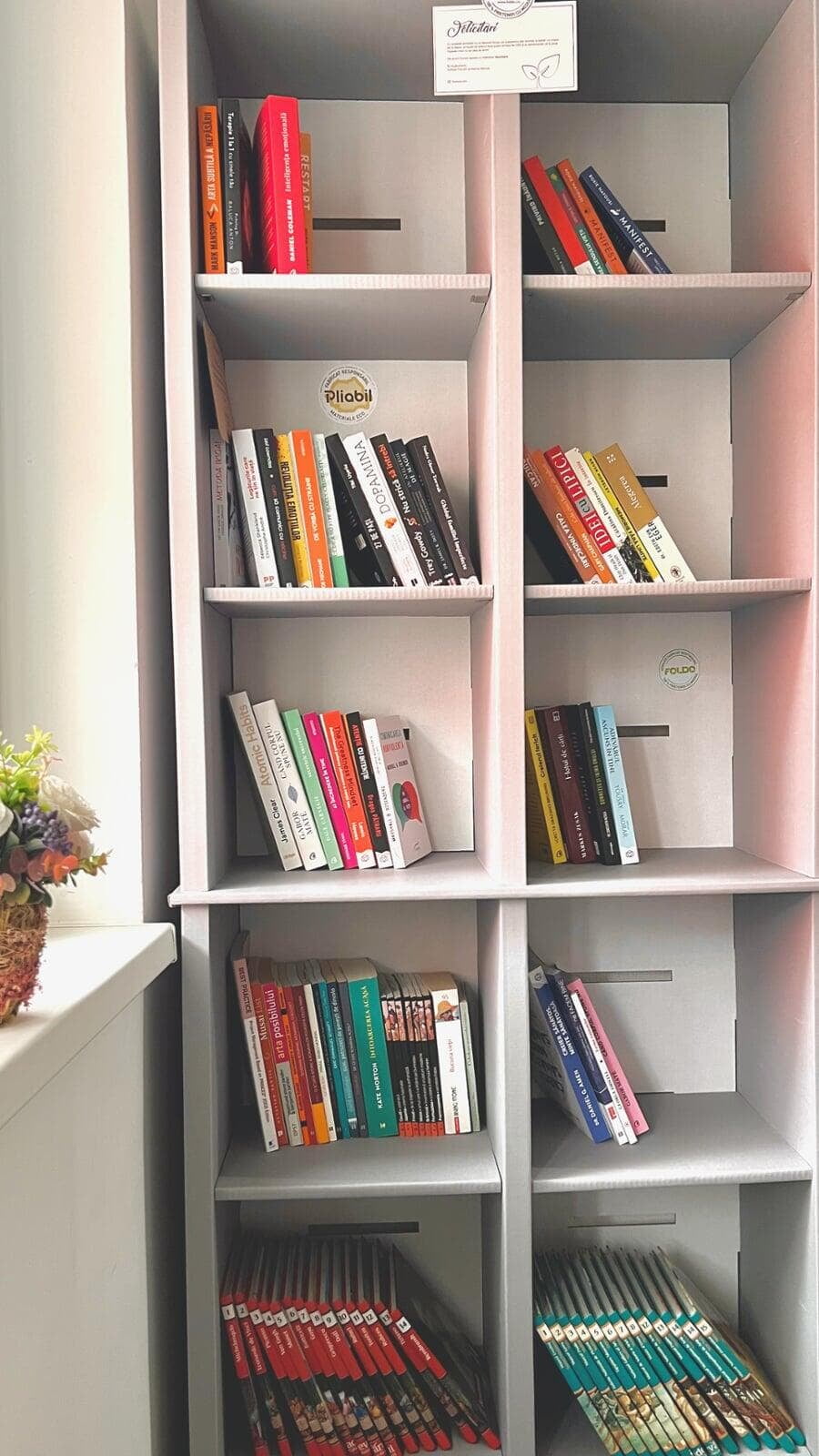

STAFF FACILITIES

Providing staff facilities is essential because it demonstrates care and appreciation for employees,

fostering a sense of belonging and loyalty while also boosting morale and productivity.

Employees Library

Modern Lunch Room

Private Parking Lot

Dedicated Meeting Room

Professional Development Trainings